As China’s exports of high-speed trains and aircraft reach record levels, a revolutionary maintenance technology is emerging from Xi’an Jiaotong University that could redefine global equipment inspection standards. Professor Chen Xuefeng’s team at the iHarbour Academy of Frontier Equipment has developed a biomimetic snake-shaped robot capable of navigating complex machinery like aviation engines without disassembly – a technological leap that addresses growing demands for efficient maintenance solutions in precision industries.

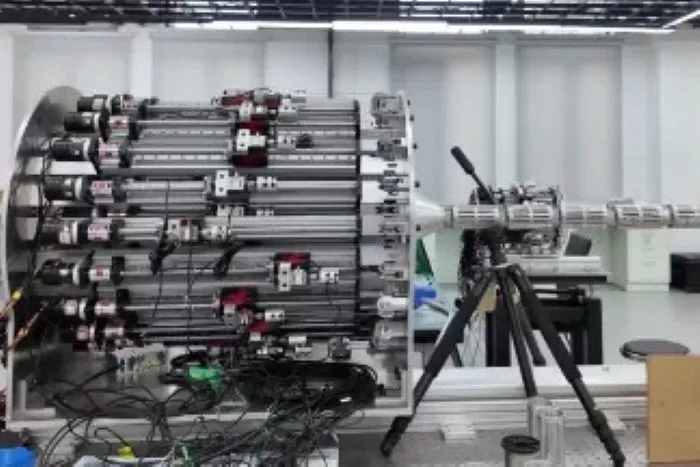

The innovation solves a longstanding industry dilemma. Traditional inspection methods for critical components like jet engines required complete disassembly, consuming hundreds of labor hours and risking damage to sensitive parts. “Our solution performs what we call ‘industrial minimally invasive surgery,’ achieving comprehensive diagnostics while leaving equipment intact,” Professor Chen explained during a laboratory demonstration. The serpentine design mimics biological flexibility while maintaining robotic precision, allowing navigation through tortuous internal components that baffle conventional rigid-arm robots.

Technical challenges overcome by the team include positional drift in extended flexible systems and stability maintenance in confined spaces. Through advanced material engineering and control algorithms, the robots now achieve sub-millimeter accuracy even when operating several meters into machinery. Early adoption trials have demonstrated 70% time savings compared to traditional disassembly inspections, with the added benefit of preventing potential damage from repeated equipment breakdowns.

While initially developed for aerospace applications, the technology’s adaptability has shown promise across multiple high-stakes industries. Nuclear power plants have tested prototypes for reactor vessel inspections, where radiation exposure limits human intervention. Energy companies envision applications for underground pipeline networks, where the robots could detect microfractures before they develop into leaks. Professor Chen emphasizes that such innovations follow his research philosophy: “True breakthroughs often plant seeds whose value only becomes apparent when future challenges emerge.”

With final certification testing underway, the snake robots are preparing for their first operational deployment in commercial aviation engine inspections later this year. Industry analysts predict the technology could reduce aircraft maintenance downtime by 40%, a critical advantage as global demand for Chinese aerospace equipment grows. The development positions China at the forefront of a new era in industrial maintenance, where sophisticated robotics merge with biological inspiration to solve engineering challenges once considered insurmountable.

Related Topic:

- Rosewood Beijing’s ‘Taste of Spring’ Menu Brings Literary Inspiration to the Table

- German Entrepreneur Brews Yunnan’s Coffee Revolution

- Michelin-Starred Chef Ugo Rinaldo Hosts Tea-Inspired Countryside Dinner in Zhejiang